Improving the performance of our already outstanding ISO turning insert program

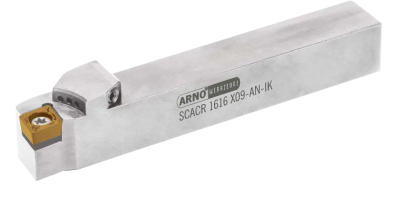

Through Coolant Indexable Turning Tools from ARNO

For Traditional and Swiss Lathe Tooling Applications

ARNO has developed some of the industry's best through coolant turning tools, some of which feature the latest in Additive Manufacturing technology.

Swiss Lathe Tooling and Traditional CNC Platforms

We take ISO Turning operations seriously

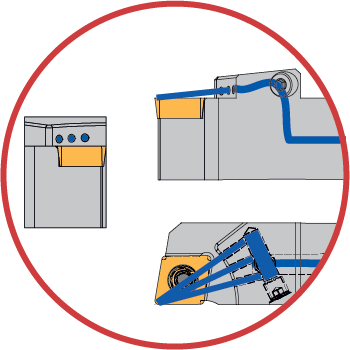

3D Hybrid Technology

Unrestricted Coolant

IK1 Traditional

Product Categories

3D Hybrid Tool Holders

3D printed to provide the most efficient flow from the coolant induction port to the cutting edge. This premium series of tool holders is on the cutting edge of through coolant technology and accommodates both ISO Positive and ISO Negative turning inserts

Go to 3D Hybrid Tool Holders

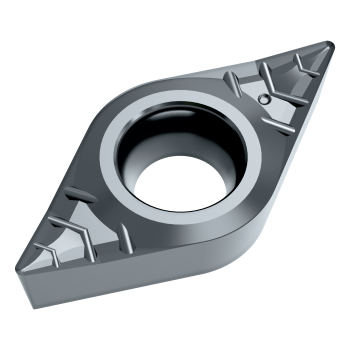

DLC Coated ISO Positive Precision Turning Inserts

In a class all their own, these Positive Precision inserts are coated with Diamond Like Carbon for machining abrasive non-ferrous materials. Choose the AD2 grade as a cost effective PCD alternative for Glass Reinforced Plastics (GRP).

Go to DLC Coated ISO Positive Precision Turning Inserts

IK1 Through Coolant Swiss Lathe Tooling

The perfect through coolant Swiss lathe tooling solution. Targeted coolant ports direct the coolant directly to the cutting edge for longer tool life and greater chip control.

Go to IK1 Through Coolant Swiss Lathe Tooling

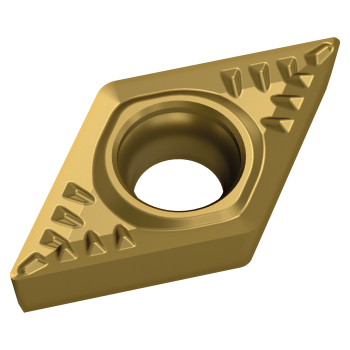

ISO Positive Precision Turning Inserts

Peripheral ground for precision indexing and sharper edge definitions. Perfect for small diameter work where part deflection must be avoided. Sharp edges and precise hones are also necessary for machining difficult materials like Titanium, Stainless Steel, and High Temp alloys.

Go to ISO Positive Precision Turning Inserts

ISO Positive Utility Turning Inserts

Less costly but not less effective. Utility turning inserts are as-pressed or precision pressed. They offer more robust edge definitions for larger work and tougher operations.

Go to ISO Positive Utility Turning Inserts

ISO Turn & Thread for AFC

The ARNO Fast Change system features ISO standard quick change turning and threading tool holders in various leads and configurations that will suit almost any application. The through coolant ports direct copious amounts of coolant to the cutting edge for better tool life and optimum chip control.

Go to ISO Turn & Thread for AFC

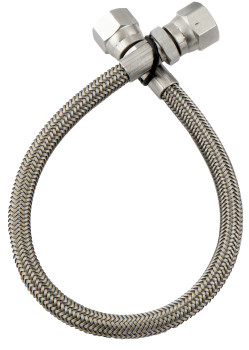

Through Coolant Plumbing Components

ARNO USA stocks the high pressure lines, fittings, and adapters needed to deliver coolant from your machine to your through coolant tool. Here is where you will find hard to locate BSPP (or "G" thread) fittings for the ARNO FAST CHANGE system and NPT fittings for coolant supplied parting, grooving, and turning tools.

Go to Through Coolant Plumbing Components