Solutions

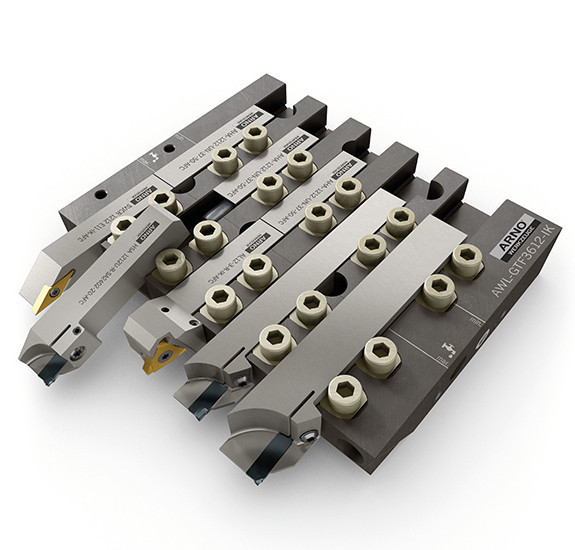

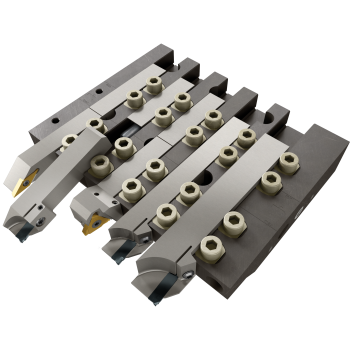

ARNO Fast Change (AFC system); Swiss Lathe Tooling System

It's the comprehensive quick change tooling solution for your Swiss machine. The program consists of an innovative through coolant gang plate and split shank tooling that work as a complete system to give you 30 second tool changes that repeat within +/-.001". Spend less time changing tools and more time making parts.

Go to ARNO Fast Change (AFC system); Swiss Lathe Tooling System

Through Coolant Indexable Turning Tools

Through coolant ISO Positive and ISO Negative turning tool holders including the new 3D Printed Hybrid line.

Go to Through Coolant Indexable Turning Tools

HTE 3 Edge Grooving

Arno's HTE 3 edge through coolant grooving system... is the perfect combination of performance and economy. Precision ground inserts ensure precise location and groove tolerance while mitigating cutting pressure. The dual port coolant extends tool life and reduces failure.

Go to HTE 3 Edge Grooving

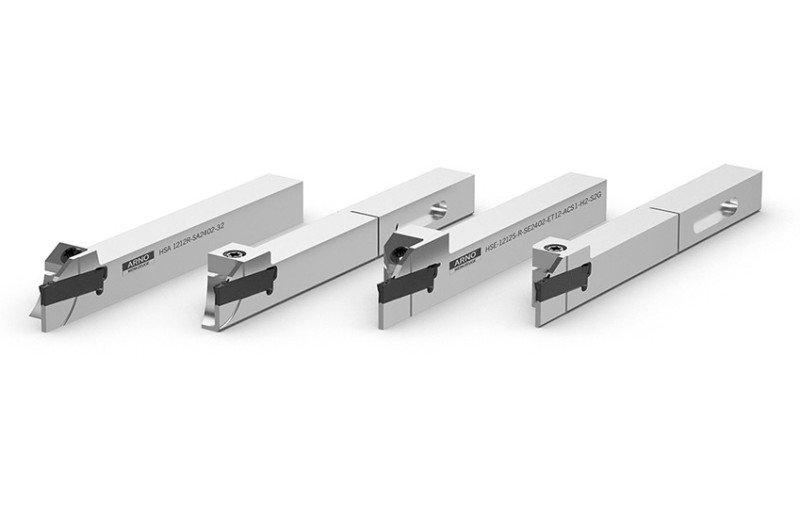

SA Parting & Grooving

ARNO has taken ordinary parting tools to an extraordinary level. By incorporating the patented ARNO Cooling System that provides maximum coolant to the cut zone, we’ve engineered world-class productivity into our SA Parting and Grooving tools.

Go to SA Parting & Grooving

SE Groove & Copy Turn

The SE Groove and Copy Turn system is capable of grooving, parting, and copy turning in a wide range of component sizes, ranging from miniature to large. It’s especially helpful on CNC Swiss lathes, where you’re limited to 5 or 6 stations to perform all external turning operations. Turning and profiling between shoulders can now be done with one tool, all while the full radius insert option enables you to blend complex features more smoothly.

Go to SE Groove & Copy Turn

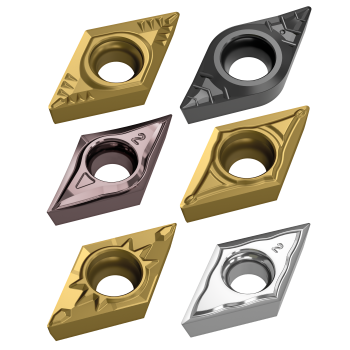

ISO Positive Turning Inserts

For an industry standard… it’s pretty outstanding. ARNO’s ISO turning insert program is an extraordinary part of our overall suite of solutions for traditional and Swiss late tooling applications. Our utility “as-pressed” collection is perfect for cost effective machining in nearly every common material. Step up to the precision program for Swiss machining where tolerances are more critical.

Go to ISO Positive Turning Inserts

NC Face Grooving

The NC Grooving System is a versatile system capable of face grooving, OD grooving, ID grooving, and groove and copy turning applications. The system is adaptable to your CNC lathe via square shank back ends or industry-standard adaptors. The NC grooving insert selection is just as versatile, offering precision peripheral ground geometries, robust as-pressed geometries, and ARNO’s venerable ALU up sharp geometry for your non-ferrous applications.

Go to NC Face Grooving