Through Coolant and Traditional Grooving & Parting Tools

SA Series Parting and Grooving System Overview

ARNO SA Parting and Grooving tools... the only system you will need

Parting and Grooving, the ARNO USA Way

Through Coolant Parting and Grooving

Parting and Grooving Perfection

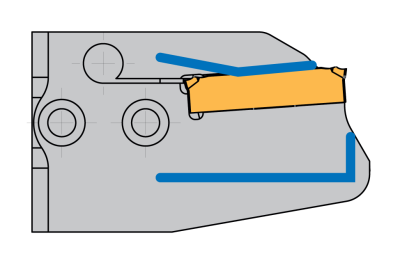

Patented ACS2 Coolant Delivery

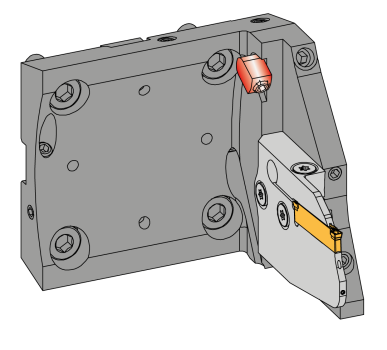

Multiple Adaptations to Your Machine

Product Categories

Industry Standard Parting and Grooving Tool Adaptors

ARNO USA offers a wide range of industry standard adapters for parting blades. Find your fit based on connection type, blade compatibility, and maximum parting diameter.

Go to Industry Standard Parting and Grooving Tool Adaptors

Machine Specific Parting and Grooving Tool Adaptors

Within our SA range of cutting tools and inserts is a large selection of machine-specific parting tool adapters. Select the best parting blade adapter for you to use based on manufacturing equipment brand, connection/bolt pattern, and maximum parting diameter to get the best machining results.

Go to Machine Specific Parting and Grooving Tool Adaptors

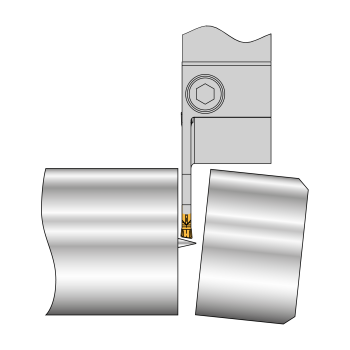

Parting Blades

The traditional lathe parting tool blade can now be upgraded on your CNC lathe with ARNO's reinforced through coolant blades.

Go to Parting Blades

Parting Modules

Our modular system of parting tools is the most flexible and reliable on the market. Offered in ACS1 and ACS2 coolant delivery. ARNO parting tools are able to be adapted to a range of square shank, industry standard (PSC, KM, VDI, etc...), and machine specific back ends.

Go to Parting Modules

SA Monoblock Parting & Grooving Tool Holders

Our Monoblock range of SA parting tools are available in inch and metric shanks from 5/16" (8mm) to 1.25" (32mm) and feature ACS1 and ACS2 coolant delivery options.

Go to SA Monoblock Parting & Grooving Tool Holders

SA Parting and Grooving Inserts

Our SA range of inserts include world class grades and geometries that are competent in machining materials ranging from Aluminum to high temperature alloys.

Go to SA Parting and Grooving Inserts

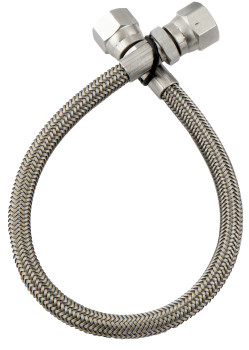

Through Coolant Plumbing Components

ARNO USA stocks the high pressure lines, fittings, and adapters needed to deliver coolant from your machine to your through coolant tool. Here is where you will find hard to locate BSPP (or "G" thread) fittings for the ARNO FAST CHANGE system and NPT fittings for coolant supplied parting, grooving, and turning tools.

Go to Through Coolant Plumbing Components